Ballast water management system

Padding top: normal

Padding bottom: normal

Background: white-500

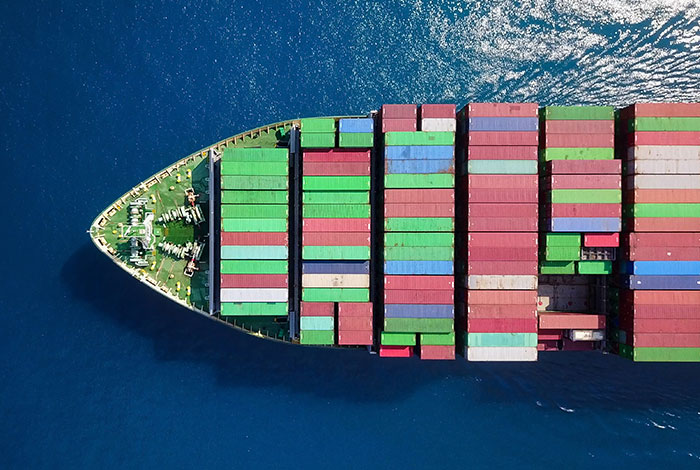

The Evac Evolution ballast water management system (BWMS) is based on a combination of filtration and UV technologies. A key aspect of the system is its precise adjustment to different seawater qualities, which ensures effective disinfection while saving on power thanks to an advanced UV light transmittance (UVT) feedback loop.

Padding top: none

Padding bottom: normal

Background: white-500

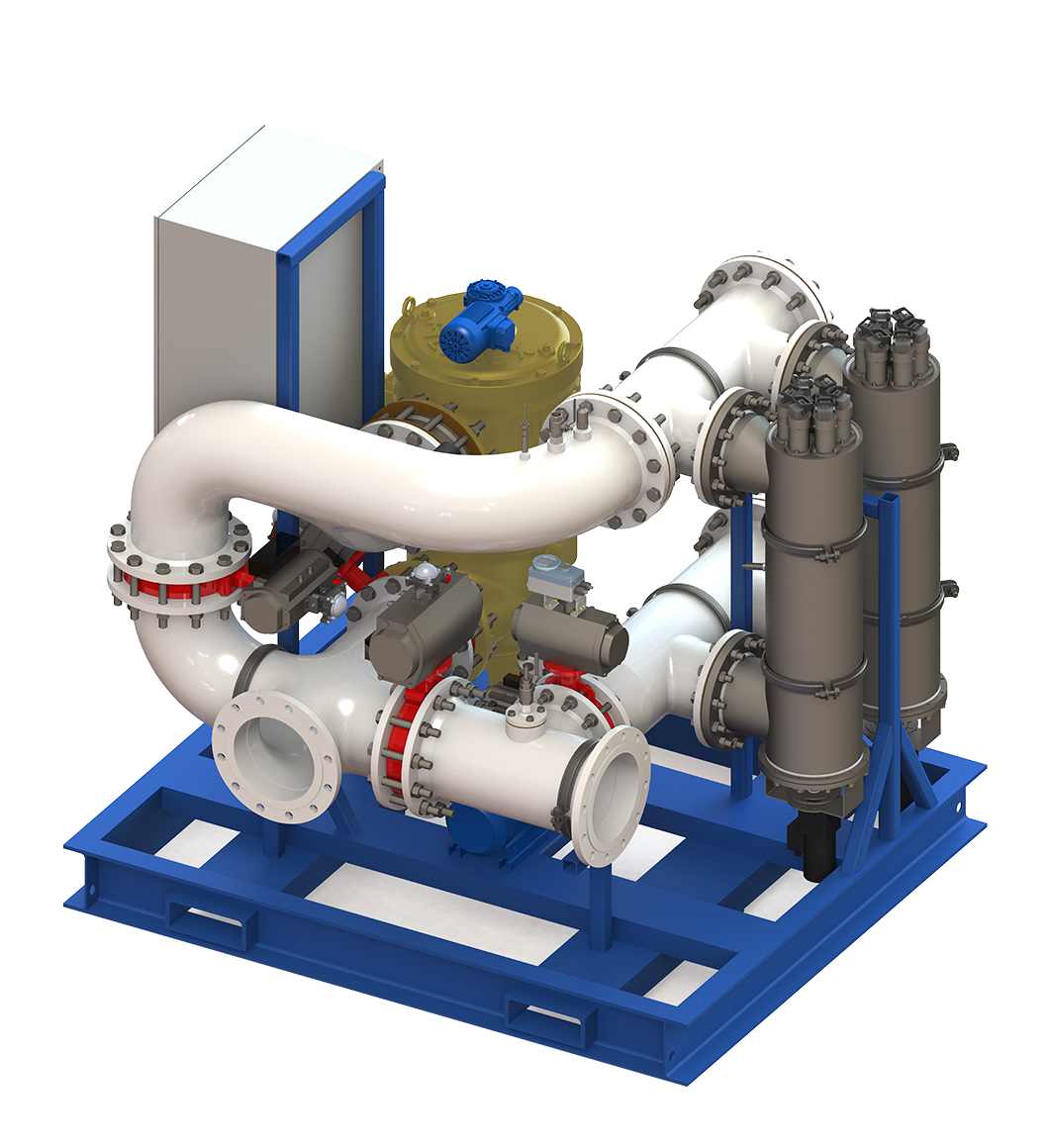

Evac Evolution BWMS units are available with capacities ranging from 34 m3/h to 1,500 m3/h. The equipment can be provided skid-mounted or in modular form to simplify retrofit installations where there is a need to economize on space.

Developed by Cathelco (part of the Evac Group), Evac Evolution complies with the revised IMO “ballast water management code” and U.S. Coast Guard regulations

Padding top: loose

Padding bottom: normal

Background: white-500

Key features of the Evac Evolution

- Saves on space and energy consumption

- Precise adjustment to different water qualities

- Helix through UV chambers prolongs seawater’s exposure to the reactor

- Intuitive control systems

- Flexible installation options making best use of available space

- Small service areas economize on footprint.

Padding top: normal

Padding bottom: none

Background: white-500

The technology behind Evac Evolution

Padding top: none

Padding bottom: tight

Background: white-500

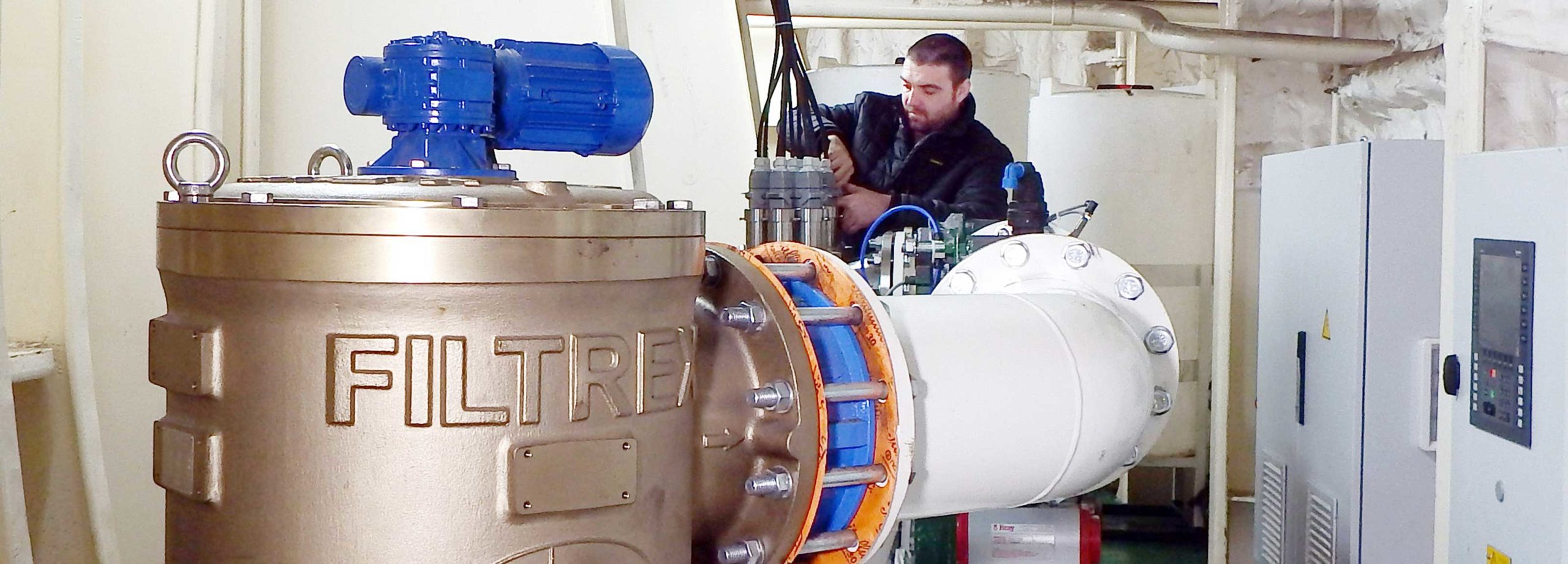

The Evac Evolution BWMS uses filtration and UV technologies. During uptake, the seawater passes through the filtration unit, where larger organisms and sediment are removed.

Padding top: none

Padding bottom: tight

Background: white-500

To allow for different water qualities, before the seawater reaches the UV chambers a measurement is taken using a UV transmission sensor. The sensor measures the UV light transmittance of the sample – the amount of UV light actually passing through the water. The power supplied to the lamps is automatically adjusted to optimize power usage.

At regular intervals, material retained in the filter is automatically backflushed and discharged at the original ballasting site, with minimal reduction of the ballast water flow during this process. The seawater then continues to UV treatment, where smaller organisms, bacteria, and pathogens are rendered harmless before the water passes to the ballast tanks.

The performance of the lamps is constantly monitored by UV intensity meters that indicate when cleaning, replacement, or refurbishment are necessary.

During ballast discharge, the seawater bypasses the filter unit and goes directly into the UV chambers, where it is treated for a second time. This avoids the risk of any contamination due to regrowth in the ballast tank.

Sampling points located in the pipework before and after the BWMS enable laboratory specimens of seawater to be taken by the relevant port authority if required.

Padding top: tight

Padding bottom: tight

Background: white-500

Padding top: normal

Padding bottom: normal

Background: white-500

With Evac Evolution BWMS, your ships can go anywhere – marine, brackish or fresh water

Because the Evac Evolution system is equally effective in marine, brackish, and fresh water, there is no restriction on areas where your vessel can trade. It can operate in the Great Lakes, inland waterways, and estuaries, whilst also remaining effective in seawater with temperatures as low as -2°C.

Effective in challenging water conditions

Some ballast water management systems struggle to operate effectively in the heavily silted water found in harbors. Evac’s system has been shown to work in waters where UVT is as low as 55%, compared with normal seawater levels of 75%.

Enhanced UV chamber design

The UV reactor is designed to increase the level of irradiation in order to meet the U.S. Coast Guard’s “live/dead” standard, whilst other features of the chambers extend the reactor’s exposure time with the seawater. For example, as well as being guided into a helix flow as it enters the reactor, the water’s path is interrupted to cause a lateral movement. This brings organisms from the edge of the flow into closer contact with the UV light, in a cycle that is repeated as the water passes along the chambers.

Precise adjustment to water quality saves power

Because it only requires maximum power in certain circumstances, such as when the ship is operating in the heavily silted waters of harbors and estuaries, Evac Evolution adjusts its power usage according to demand.

Stepless power control saves energy

Often, the power supplied to the lamps in a BWMS is increased in large increments, which inevitably leads to wastage. In contrast, the Evac Evolution system uses the latest switch-mode technology to provide a power supply that adjusts smoothly. This means that the demand from the lamps is met without any large steps that would result in excessive power use. As it is linked to data from the UV transmission and UV intensity meter feedback loop, the power output is always at an optimum level.

Easy-to-use controls

The control system for Evac Evolution is straightforward and intuitive to use. Schematics display the routing of the water through the pipework, and readings are immediately available from all sensors. The transition state of valves is also shown to give engineers a complete picture of the system’s performance.

Padding top: tight

Padding bottom: loose

Background: white-500

Padding top: normal

Padding bottom: normal

Background: white-500